PVC engineering plastics_ POM plastic Chinese name and English name

POM is a kind of engineering plastics. Its Chinese name is polyoxymethylene, or saigang. Its chemical name is polyoxymethylene, while its English name is acid resin, polyoxymethylene, polyacetal, or POM for short. POM is divided into Homo POM and co POM.

Polyoxymethylene (acetal resin) is a crystalline thermoplastic resin.

POM consists of homopolymer composed of polyoxymethylene molecular chain composed of formaldehyde, and copolymer composed of trimer of aldehyde - trioxyheterocyclohexane and ethylene oxide. Steel is the representative of this kind of copolymer.

It mainly plays its role in the category of mechanical components such as gears and bearings. Polyoxymethylene is milky white and opaque, a high-density, high crystalline linear combination without side chains. It has outstanding comprehensive functions, excellent fatigue resistance and creep resistance, excellent electrical functions, etc.

1. Mechanical function: high elastic modulus, high hardness and stiffness. It can be used at -40~100 degrees for a long time. And it can withstand repeated impact for many times with little change in strength. The strength is little affected by temperature and temperature change. Polyoxymethylene (POM) is the kind of thermoplastic material with the most excellent fatigue resistance and small creep.

2. Thermal function: polyoxymethylene has a high thermal deformation temperature, 136 degrees for homopolymerization and 110 degrees for copolymerization. Copolyformaldehyde has higher continuous operating temperature. Copolyformaldehyde can be used continuously at 114 ℃ for 2000h, or at 138 ℃ for 1000h. The temperature that can be used in a short time can reach 160 ℃. According to American UL specification, the long-term heat-resistant temperature of polyoxymethylene is 85~105 ℃.

3. Chemical resistance: polyoxymethylene has no room temperature compatibilizer and has appropriate good corrosion resistance under high temperature conditions. And the size and mechanical strength change little. It has good compatibility and is easy to color.

4. Electrical function: its dielectric constant is not affected by temperature and humidity.

5. The disadvantages of the function of POM: relatively high density, opaque and acid resistant; Large forming shortening rate; Melting electricity is not very high; The heat drop point is appropriate and agile at higher temperatures. Thermal oxygen degradation also occurs in the presence of oxygen.

Forming process of POM

Polyoxymethylene can be processed by general thermoplastic forming methods, such as injection molding, extrusion, blow molding, spraying, etc.

Injection molding is the primary processing method.

Polyoxymethylene is usually injected by screw injection molding machine, and the injection amount of products should not exceed 75% of the maximum injection amount of the molding machine.

Generally, the injection molding process of polyoxymethylene can be referred to as follows: the barrel temperature is 175~195 ℃, the mold temperature is 45~75 ℃, the injection pressure should be set within the range of 69~118mpa, and the forming cycle can be taken as 20~30s.

The article comes from PVC Engineering Plastics:http://www.wywantong.com/

-

04-13

PVC Engineering Plastics: how PVC plastic pipes are formed

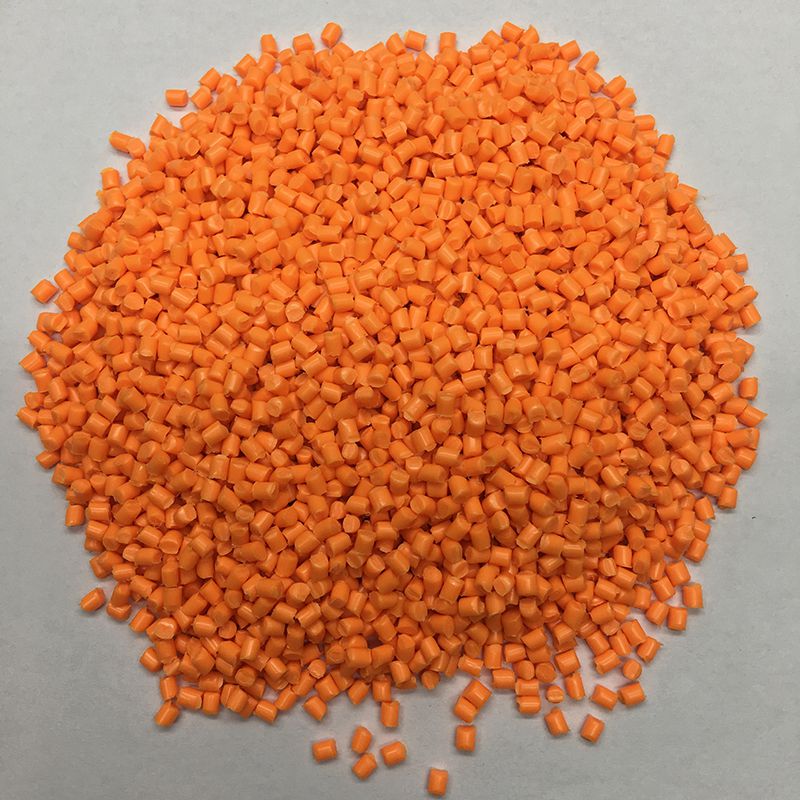

The forming process of PVC plastic pipes should start from the raw materials of PVC plastic granules, which can be divided into soft PVC and hard PVC according to the added amount of stabilizer, plast

-

11-12

What is the filling property of Jiangmen engineering plastics

What is the filling property of Jiangmen engineering plasticsIn recent years, PC modified plastics have developed rapidly in China, and its industrial system is gradually established and improved. Th

-

10-08

Jiangmen Engineering Plastics: how to classify Jiangmen engineering plastics?

How to classify Jiangmen engineering plastics? 1. Classification by application characteristicsAccording to the different application characteristics of famous plastics, plastics are usually divided

-

08-30

Application scope of PBT engineering plastics

PBT engineering plastics are widely used in electronics, car industry, office machinery and other fields. In Japan and the developed countries in Europe, PBT engineering plastics are mainly used in t