What are the performance characteristics of Jiangmen engineering plastics?

(1) light product quality: the specific gravity of engineering plastics is generally about 0.83 ~ 2.2, only 1/9 ~ 1/4 of steel and 1/2 of aluminum. Some engineering plastics, such as polypropylene, are much lighter than water. This characteristic of plastics is of great significance to the mechanical equipment that requires to reduce its self weight, such as vehicles, ships and aircraft.

(2) high specific strength: for materials with equal volume, the strength of engineering plastics is generally lower than that of metal. However, because engineering plastics are much lighter than metal, when compared with equal weight, the strength of some engineering plastics is much higher than that of general metal, which is the highest strength material in the existing structural materials. For example, the tensile strength per unit weight of glass fiber reinforced epoxy resin is about 2 times higher than that of ordinary steel.

(3) good chemical stability: engineering plastics generally have excellent corrosion resistance to acid, alkali and other chemicals, which is a very significant advantage. Among them, polytetrafluoroethylene and polyether chloride have excellent corrosion resistance, and have broad development prospects in chemical anti-corrosion equipment.

(4) excellent electrical function: almost all engineering plastics have superior electrical insulation function, minimal dielectric loss and excellent arc resistance, which can be compared with ceramic, rubber and other insulating materials. Therefore, the application of engineering plastics in motor, electric appliance and electronic industry has a very broad prospect.

(5) excellent friction reducing and wear-resisting functions: by using this feature, various self-lubricating bearings, gears and sealing rings can be made of engineering plastics. Engineering plastics also have excellent embedment to foreign matters, which is particularly important for their application in the harsh conditions with abrasive particles or impurities.

(6) excellent shock absorption and noise elimination effect: machinery equipped with engineering plastic bearings and gears can reduce vibration, weaken noise and even achieve noise elimination.

(7) convenient forming and processing: engineering plastic products can often be formed at one time, while metal products have to go through several, dozens or even dozens of processes to complete the processing. This characteristic of engineering plastics is of great significance for saving man hours and improving labor productivity. The machining of plastics is also relatively simple.

This article is from Jiangmen Engineering Plastics:http://www.wywantong.com/

-

04-13

PVC Engineering Plastics: how PVC plastic pipes are formed

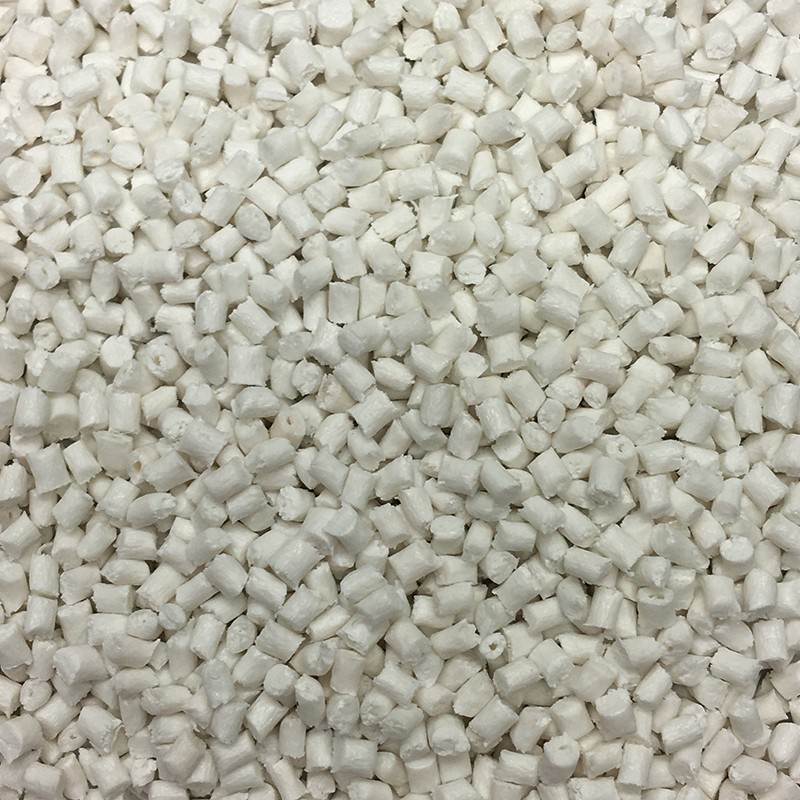

The forming process of PVC plastic pipes should start from the raw materials of PVC plastic granules, which can be divided into soft PVC and hard PVC according to the added amount of stabilizer, plast

-

11-12

What is the filling property of Jiangmen engineering plastics

What is the filling property of Jiangmen engineering plasticsIn recent years, PC modified plastics have developed rapidly in China, and its industrial system is gradually established and improved. Th

-

10-08

Jiangmen Engineering Plastics: how to classify Jiangmen engineering plastics?

How to classify Jiangmen engineering plastics? 1. Classification by application characteristicsAccording to the different application characteristics of famous plastics, plastics are usually divided

-

08-30

Application scope of PBT engineering plastics

PBT engineering plastics are widely used in electronics, car industry, office machinery and other fields. In Japan and the developed countries in Europe, PBT engineering plastics are mainly used in t