What are the functional characteristics of PBT engineering plastics

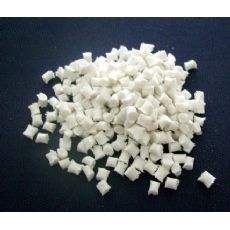

PBT material. Pppetpbt not belonging to engineering plastics can become engineering plastics after being reinforced; For another example, after PA is reinforced with 30% glass fiber, its creep resistance advances four times; For another example, after PC was reinforced with 30% glass fiber, its creep resistance and fatigue resistance increased by 5~7 times and 5 times respectively Therefore, when selecting materials, it should be noted that although the pure resin function of some plastic varieties can not meet the demand, it may completely meet the demand after modification For some stressed finished products, in addition to the above functions.

1. Tensile strength, bending strength and modulus: these plastic varieties with good functions include pompapcppopsf and PI, as well as corresponding glass fiber reinforced materials and glass fiber reinforced materials such as petpbtpp

2. Impact strength: PC is the best, pompopsf is the second, pphpvcpa6pa66 chlorinated polyether and other varieties have high low-temperature brittleness

3. Creep resistance: the creep resistance of thermosetting plastics is better than that of thermoplastics The creep resistance of pcppopsfpi and par is better than that of abspahpvcpom

4. Fatigue resistance: the fatigue resistance of several plastics is pom> PBTPET> PA66> PA6> The creep resistance of PP and pure PC is not good, but it can rise and fall after glass fiber reinforcement, close to pom

5. Standard stability the standard stability of pcppopsfpiparpespps is good, which can be used for the selection of plastic products with accuracy above grade 3; However, the standard stability of papom and high crystalline plastics is not high, and it is only applicable to the selection of plastic products with accuracy below grade 5

Article source: PBT engineering plastics http://www.wywantong.com/

-

04-13

PVC Engineering Plastics: how PVC plastic pipes are formed

The forming process of PVC plastic pipes should start from the raw materials of PVC plastic granules, which can be divided into soft PVC and hard PVC according to the added amount of stabilizer, plast

-

11-12

What is the filling property of Jiangmen engineering plastics

What is the filling property of Jiangmen engineering plasticsIn recent years, PC modified plastics have developed rapidly in China, and its industrial system is gradually established and improved. Th

-

10-08

Jiangmen Engineering Plastics: how to classify Jiangmen engineering plastics?

How to classify Jiangmen engineering plastics? 1. Classification by application characteristicsAccording to the different application characteristics of famous plastics, plastics are usually divided

-

08-30

Application scope of PBT engineering plastics

PBT engineering plastics are widely used in electronics, car industry, office machinery and other fields. In Japan and the developed countries in Europe, PBT engineering plastics are mainly used in t