How to solve the problem of odor in Jiangmen engineering plastics

Many compounds in engineering plastics have unpleasant odor, including amine, phenol, mercaptan, peroxide, benzene, aldehyde, ketone and some plasticizers and flame retardants. The solvents used in the processing of engineering plastics also emit a strong chemical smell. What should I do if engineering plastics have smell?

Use low odor substitutes to replace those unpleasant additives, and reduce the amount of residual monomers in engineering plastics. Gas adsorbents and antibacterial agents are added to engineering plastics to prevent unpleasant odor due to the action of bacteria and fungi. Solvent extraction and waste gas can reduce the residual odor in the recycling process of engineering plastics.

1. Relatively pure resin for raw materials

In many engineering plastics, especially in PVC, styrene, poly (ethyl acetate), acrylate and other engineering plastics, the residual monomers will produce unpleasant odor, and the use of odorless resin is also very effective.

2. Aromatics addition

Aromatics in engineering plastics can not eliminate these odors, but can play a shielding role. The method can be applied to polyethylene, polypropylene and polyolefin thermoplastic elastomers, and the processing methods include injection molding, extrusion or blow molding.

3. Selection of additives

Many extenders, such as amine extenders, usually have strong pungent odor in production. This problem can be effectively solved by substituting other additives with the same effect. For example, polyhydroxy compounds are used to replace tertiary amine catalysts, zinc stabilizers are used to replace phenol stabilizers for PVC base or calendering, and plant extracts, such as erucic acid and oleic acid, have a much smaller odor than amine lubricants made from animal extracts (used for polyolefin and styrene food packaging materials).

4. Adsorbent

If a small amount of zeolite (aluminum silicate adsorbent) is filled in the polymer, the odor of the material can be removed. Molecular adsorbents have been successfully applied to polyolefin extrusion tubes, injection molding and extrusion blow molding containers, barrier packaging materials, extrusion packaging materials and sealing polymers, and odor of engineering plastic products.

5. Application of antibacterial agent

Adding antibacterial agents to engineering plastics can not only reduce odor, but also delay the surface aging, discoloration and brittleness of products. The commonly used antibacterial agents include triclosan, parathion isothiazolinone (OIT).

6. Use desorption method

The desorption method is to put the engineering plastics into the odor adsorbents such as activated carbon and high surface area silicate. The vacuum treatment environment can speed up the desorption process. The treatment of engineering plastics particles with special detergent solution can also help to remove the odor. Generally speaking, these cleaning agents are aqueous or alkaline solutions containing surfactants. These detergents can effectively remove vinyl chloride monomer, styrene, acrylate, acrylic monomer and unsaturated hydrocarbon.

7. Disposal of recycled goods

Waste engineering plastics often have unpleasant smell. Most recycled engineering plastics, such as HDPE, PP, PVC and pet, are washed in aqueous solution to remove pollutants, but the smell adsorbed inside the engineering plastics will remain.

This article is from Jiangmen Engineering Plastics:http://www.wywantong.com/

-

04-13

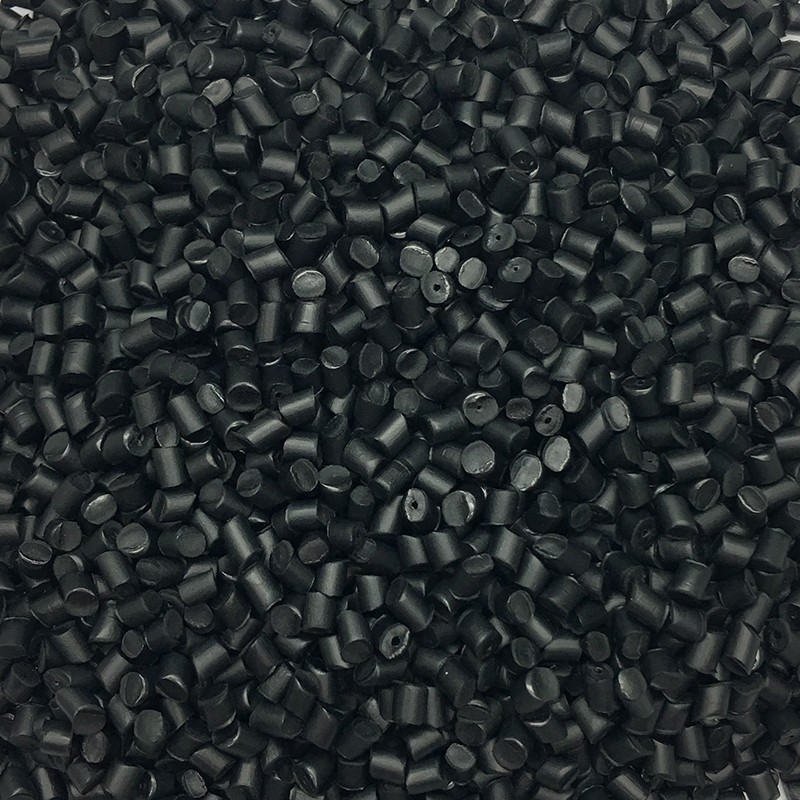

PVC Engineering Plastics: how PVC plastic pipes are formed

The forming process of PVC plastic pipes should start from the raw materials of PVC plastic granules, which can be divided into soft PVC and hard PVC according to the added amount of stabilizer, plast

-

11-12

What is the filling property of Jiangmen engineering plastics

What is the filling property of Jiangmen engineering plasticsIn recent years, PC modified plastics have developed rapidly in China, and its industrial system is gradually established and improved. Th

-

10-08

Jiangmen Engineering Plastics: how to classify Jiangmen engineering plastics?

How to classify Jiangmen engineering plastics? 1. Classification by application characteristicsAccording to the different application characteristics of famous plastics, plastics are usually divided

-

08-30

Application scope of PBT engineering plastics

PBT engineering plastics are widely used in electronics, car industry, office machinery and other fields. In Japan and the developed countries in Europe, PBT engineering plastics are mainly used in t